THERMALLOY® SPRAY COATINGS

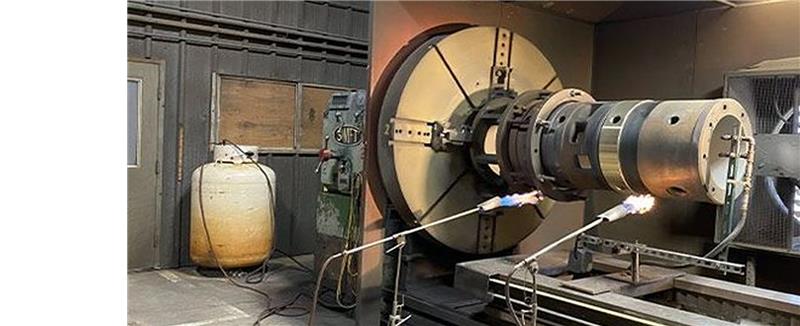

The Energy Industry counts on Exline for our revolutionary ThermAlloy® spray-coating process to repair,refurbish and improve Power Cylinder Bores and Liners. Midstream,downstream,power generation operations and more use our proprietary process to not only make equipment work,but make it work better.

ThermAlloy is an improved alternative to traditional cylinder repair—an alloy of materials featuring inherent porosity throughout its coating. It’s safer than hard chrome, costs less, lasts longer, less subject to damage and requires less turnaround time:

- Enhances durability

- Resists corrosion and wear

- Has increased porosity

- Improves oil retention and wear rates

- Is equal to or better than chrome plating

- Costs less than chrome plating

- Is safer than chrome plating

- Superior to cast iron

We also offer ThermEx® Thermal Spray Coatings for other energy infrastructure and industrial parts – cylinders, rods, shafts and more.

Equipment treated with ThermAlloy is compatible with other pre-existing components such as chrome cylinders,oils,cast iron rings and cylinders. And it’s warrantied up to 18 months or 13,000 hours from cylinder completion—providing seamless performance,long-lasting wear and maximized uptime.

Dangers of Hard Chrome

Health Issues

Hexavalent chromium is a potential cancer-causing carcinogen.

Toxic Fumes

Workers could inhale fumes released. Proper ventilation essential.

Skin Irritation

Direct contact can cause skin irritation and allergies.

Environmental Impact

If runoff were to occur, can contaminate water sources and soil.

Shortcuts Here

See Repairs & Manufacturing for work done at our facilities.

See Field Services for work onsite at your locations.

See Literature for more detailed PDFs on most Exline offerings.

See Parts & Equipment for info on components, devices, parts, etc.