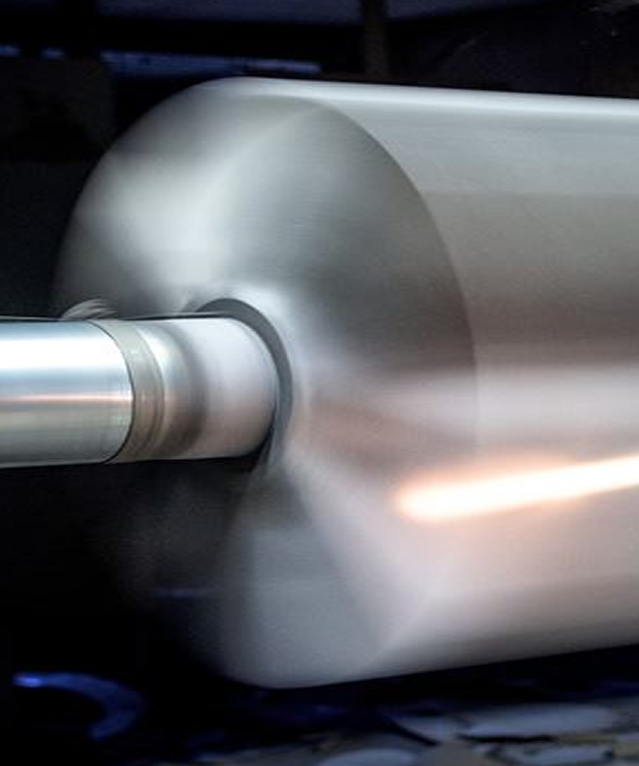

THERMEX® THERMAL SPRAY COATINGS

ThermEx spray coatings protect, enhance, refurbish, repair or improve shafts, pistons, seals, fans, rams, impellers, valves, cylinders, crossheads, saddles, rod eyes and more. For the machinery and equipment that powers up the energy industry and other heavy-duty industrial applications, ThermEx makes it work… and ThermEx makes it work better.

The process is equal to or better than chrome plating, which has longer lead times for remanufacturing, higher cost for complete repair, and concerns with toxicity and damage.

Thermal Spray Benefits:

- Restore worn parts to original dimensions

- Improve wear resistance; prolong service life

- Add corrosion protection

- Improve lubrication

- Provide near-zero running clearance

- Salvage undersized production parts

- Dissipate static on plastic or fiberglass components (Aluminum, Copper or Zinc sprays)

Thermal Coating Options (most frequently used):

- 400 Stainless Steel

- Tungsten Carbide (6-10 x the life of hard chrome)

- Aluminum Oxide Ceramic

- Zirconium Oxide Ceramic Copper

- ThermAlloy®

Thermal Process Options:

Flame Spray

- Shaft enhancement or repair

- Bearing housing enhancement or repair

- Casting repairs

- Mold dye enhancement or repair

Arc Spray

- Shaft enhancement or repair

- Enhancing electrical conductivity

- Feed roll enhancement or repair

- No slip coating solutions

Plasma Spray

- High-temperature environments

- Parts that experience a lot of wear

- Corrosion resistance

- Dielectric coatings

HVOF Spray

- Anti-fretting

- High-wear parts

- Corrosion resistance

Shortcuts Here

See Repairs & Manufacturing for work done at our facilities.

See Field Services for work onsite at your locations.

See Literature for more detailed PDFs on most Exline offerings.

See Parts & Equipment for info on components, devices, parts, etc.